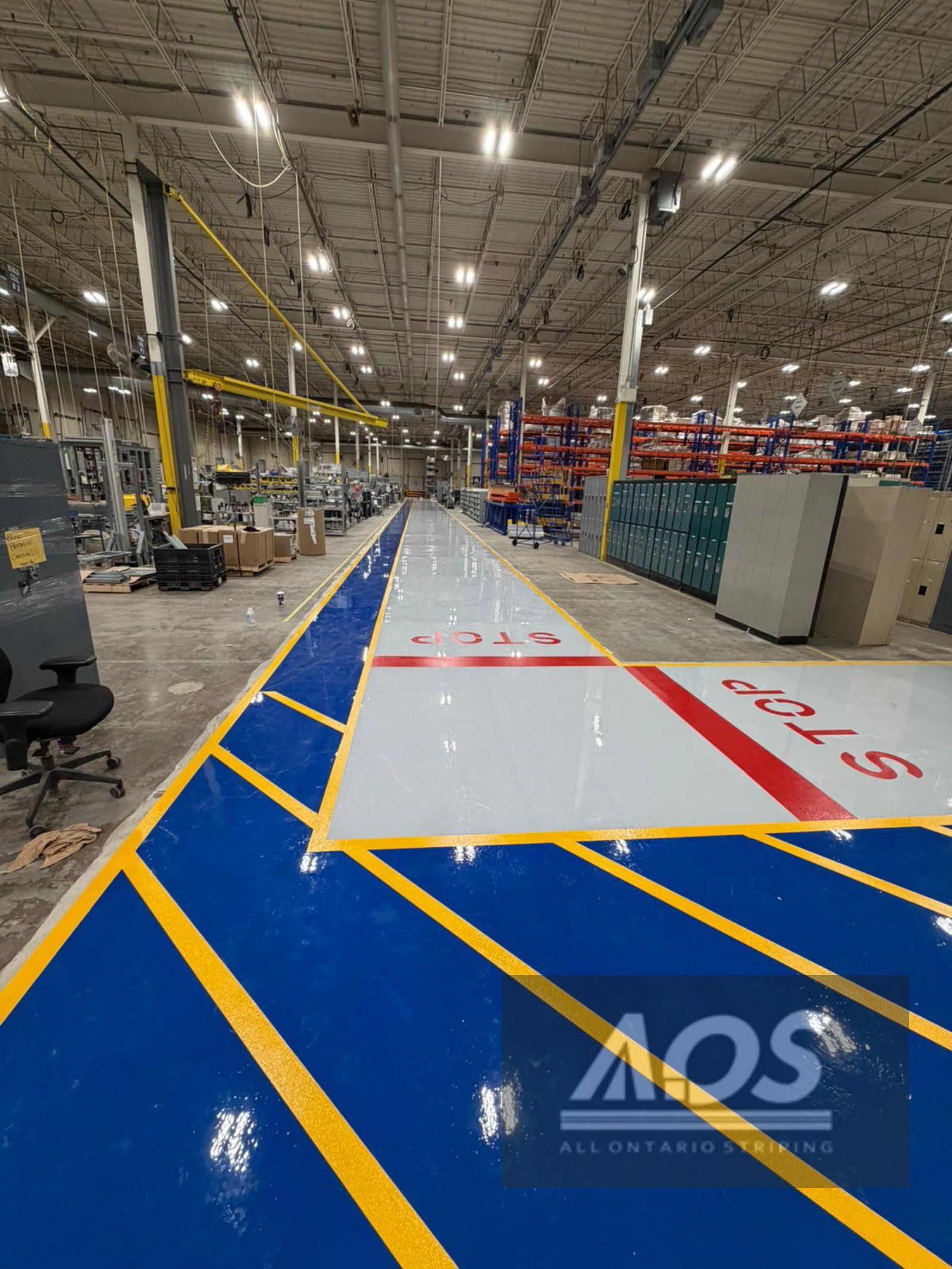

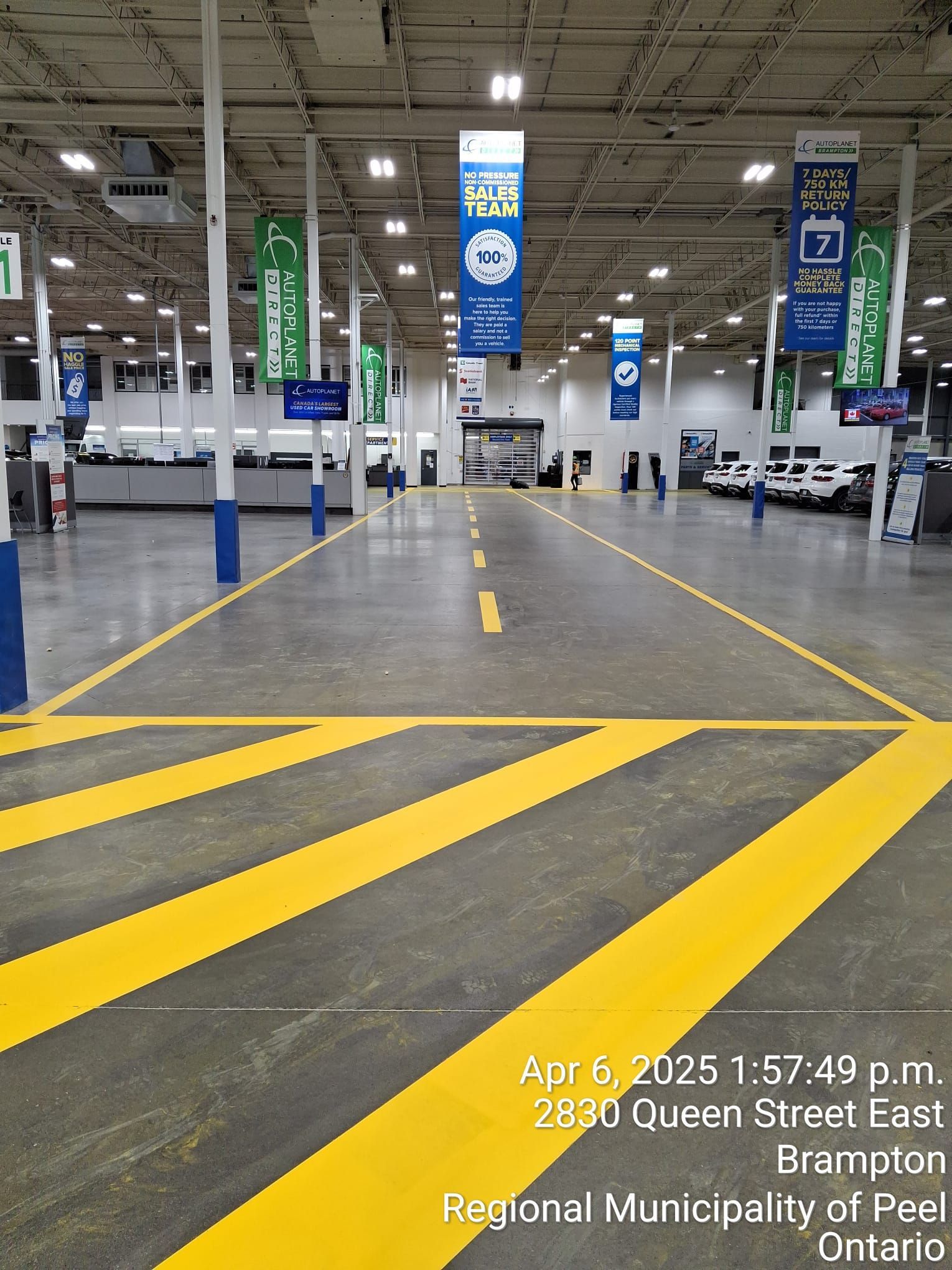

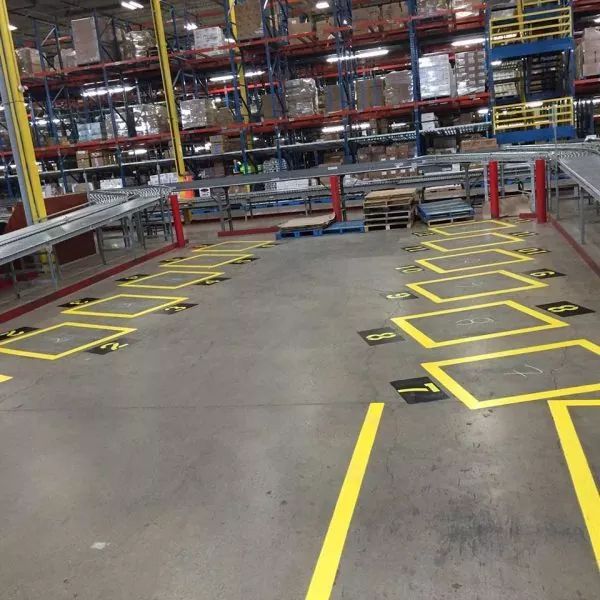

Warehouse Lines

Floor-Marking for Safety - It's the Law!

Occupational Health and Safety Regulations require workplaces to clearly mark:

- Pedestrian Pathways, and

- Passageways leading to an open door or gate

Some other markings are not required by-law, but they improve workplace safety and efficiency.

- Hazardous areas

- Different work areas

- Locations for products or equipment

- Traffic route signs

Your Floor-Marking Plan

Your floor-marking plan needs:

- Accurate cost and budget estimates

- Dependable materials

- Proper preparation techniques

- Durable outcomes

We follow three key steps.

Step 1: Determining Your Traffic Levels

How much traffic flows in your area?

Foot traffic is “light traffic.” Forklifts, pivoting wheels and dragging pallets are “heavy traffic.”

This chart helps define your traffic level.

Light

- No-traffic areas

- Infrequent foot traffic

- No carts / pallet jacks

- No trucks

- No forklifts

- Minimal or no water contact

- No chemical contact

Medium

- Regular foot traffic

- Some cart or pallet jack traffic

- Infrequent forklift or light duty truck traffic

- Potential for water and/or chemical contact

- Occasional floor cleaning or scrubbing

Heavy

- Heavy forklift traffic

- Constant foot traffic

- Heavy cart or pallet jack traffic

- Regular floor cleaning or scrubbing

- Class 2+ truck traffic

- Water and/or chemical contact

Extreme

- Constant forklift traffic

- Forklift wheel pivoting

- Dragging pallets or other items

- Class 4+ truck traffic

- Aggressive floor cleaning scrubbers

- Other major floor hazards

Step 2: Selecting Your Materials

The top choices are paint or tape.

Paint is a good choice for light to medium traffic areas. Paint is also usually the cheapest option.

Advantages of Traffic Paint

- Cheaper than other options

- Easy application

- Quick drying time

- Low fumes

Disadvantages of Traffic Paint

- Medium durability

- Flat finish paint easily holds dirt and difficult to clean

- Dirty paint becomes loose, although durability can be increased by proper floor technique

Application of a sealer over the paint makes it collect less dirt and easier to clean.

Heavy and Extreme Traffic Levels

Epoxy solutions are best for heavy and extreme traffic areas. Epoxy solutions are more expensive than traffic paint, but worth the investment.

Advantages of Epoxy Floors

- Epoxy floors have a long lifespan. Concrete is the only superior material.

- Epoxy comes in gloss and semi-gloss finishes, so it is less susceptible to dirt and easier to clean, keeping the markings bright and highly visible for a long time

Disadvantages of Epoxy Floors

- Cure time can take up to 72 hours to fully cure and reach its full strength

- Epoxy has a strong, potentially harmful odour

- Fully solid epoxies cannot be sprayed. They require significant manual taping.

Traffic Marking Tape

Advantages of Traffic Marking Tape

- Easy to Install

- Does not require loud or heavy machinery

- Odorless

Disadvantages of Traffic Marking Tape

- Less cost effective than Traffic paint

- Suitable for very light traffic areas

Step 3: Preparing Your Floor

This step is crucial. Start by preparing your concrete – it will give your floor markings longer life!

In this stage, we prepare the floor by eliminating oil and dirt, removing thin top layer exposing a clean bare unsealed surface.

Some of our main techniques are:

- Using solvents to clean floors

- Applying sealer over cured concrete – filling pores, binding dust particles and forming a water-resistant film on the surface

- Mechanical abrasion, including:

- Shot Blasting – firing small beads to strip the smooth finish surface to expose a roughened concrete surface that is ideal for adhering paint, or

- Diamond Shaving – “shaving” away 1mm to 5mm of the surface creating a channel. The paint is applied to the channel creating a recessed line level with the original floor surface.

Call us for a Free Estimate: 437-973-2292

MAKE SURE YOUR WAREHOUSE IS SAFE AND EFFICIENT

Don’t wait until faded lines cause confusion or unsafe conditions.

👉 Contact All Ontario Striping now for a free consultation and estimate.

For up-to-date photos and videos, please see our Instagram or Youtube!